Chemical Conversion Coating

Conversion-coating contamination, it manifests as thin inorganic layers on metal surfaces, formed through chemical reactions with the substrate. These coatings, they develop uniquely in humid environments, exhibiting patchy patterns that depend from exposure duration and atmospheric agents. On aluminum alloys, the contamination adheres tenaciously, which leads to persistent residues during cleaning attempts. It appears that laser ablation faces distinct challenges here, as the layers resist vaporization without substrate damage. For steel substrates, the formation shows more uniform coverage, yet removal demands precise pulse control to avoid re-deposition. This contamination, it persists under initial laser passes, demonstrating material-specific behaviors that complicate full eradication. The process yields cleaner surfaces eventually, though influenced from coating thickness variations.

Produced Compounds

Affected Materials

Aluminum

Brass

Brick

Bronze

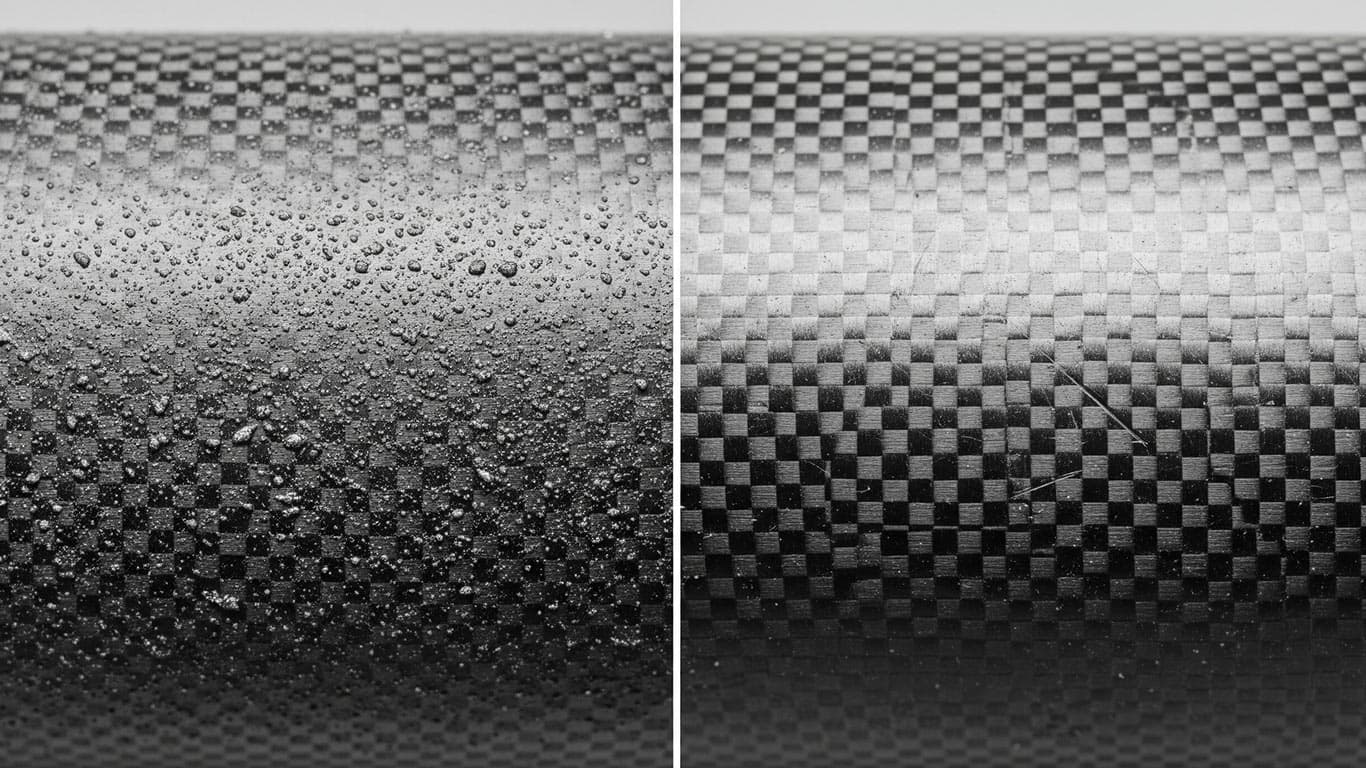

Carbon Fiber Reinforced Polymer

Cast Iron

Ceramic Matrix Composites CMCs

Concrete

Copper

Epoxy Resin Composites

Fiberglass

Granite

Iron

Limestone

Magnesium

Marble

Metal Matrix Composites MMCs

Nickel

Phenolic Resin Composites

Polyester Resin Composites

Porcelain

Sandstone

Slate

Stainless Steel

Steel

Terracotta

Titanium

Titanium Carbide

Tool Steel

Urethane Composites

Zinc

Titanium Alloy (Ti-6Al-4V)

Stainless Steel 316

Stainless Steel 304

Aluminum Bronze

Aluminum Nitride

Titanium Nitride

Chemical Conversion Coating Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more