PVD Coating Defects

PVD coating contamination, it manifests as thin inorganic layers, dependent from deposition environments. These contaminants, they exhibit unique formation patterns, like irregular clustering on metallic substrates, which leads to tenacious adhesion. In laser cleaning applications, the removal challenges arise, particularly on aluminum surfaces, where the contamination persists under short pulses. It seems that on steel, behaviors differ, showing easier delamination yet risking substrate etching. The process yields distinct outcomes, influenced from wavelength selection, that demonstrates material-specific responses. Layers detach selectively, avoiding damage to the underlying coating. Shows effectiveness in preserving integrity.

Produced Compounds

Affected Materials

Aluminum

Brass

Brick

Bronze

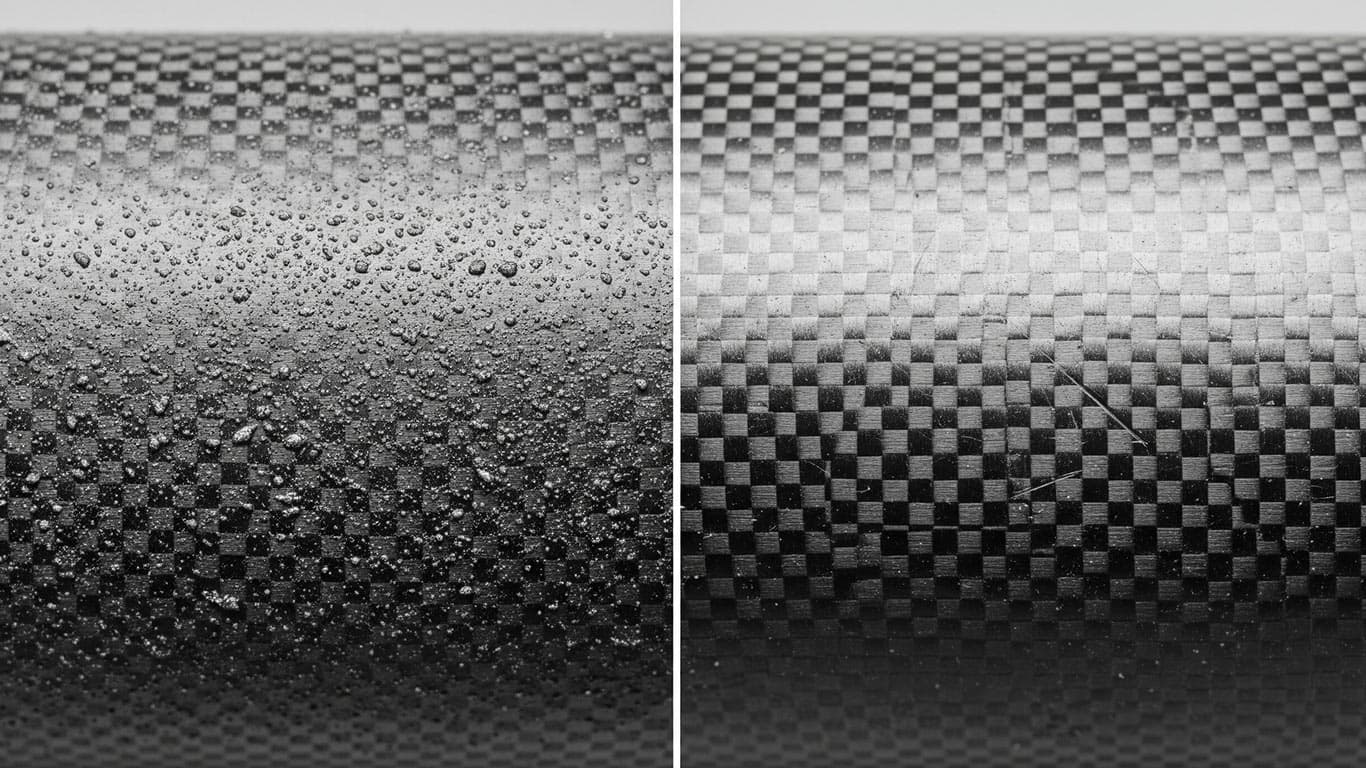

Carbon Fiber Reinforced Polymer

Cast Iron

Ceramic Matrix Composites CMCs

Concrete

Copper

Epoxy Resin Composites

Fiberglass

Granite

Iron

Limestone

Magnesium

Marble

Metal Matrix Composites MMCs

Nickel

Phenolic Resin Composites

Polyester Resin Composites

Porcelain

Sandstone

Slate

Stainless Steel

Steel

Terracotta

Titanium

Titanium Carbide

Tool Steel

Urethane Composites

Zinc

Titanium Alloy (Ti-6Al-4V)

Stainless Steel 316

Stainless Steel 304

Aluminum Bronze

Aluminum Nitride

Titanium Nitride

PVD Coating Defects Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more