Paint Primer Layers

Primer coating contamination forms unevenly during exposure to environmental factors, so buildup occurs on inorganic layers and adheres strongly to base materials. Before cleaning, surface exhibits patchy patterns because particles embed into primer matrix. Treatment applies laser energy, and removal achieves selectively without substrate damage. In observations, metal substrates show resilient contamination so challenges arise from heat sensitivity, while composites demand adjusted pulses for uniform stripping. After ablation, layer detaches easily from smooth areas yet resists in crevices. Process removes contamination effectively, and results indicate better adhesion prevention on treated surfaces. Buildup is detected mainly at edges because of primer porosity.

Produced Compounds

Affected Materials

Aluminum

Brass

Brick

Bronze

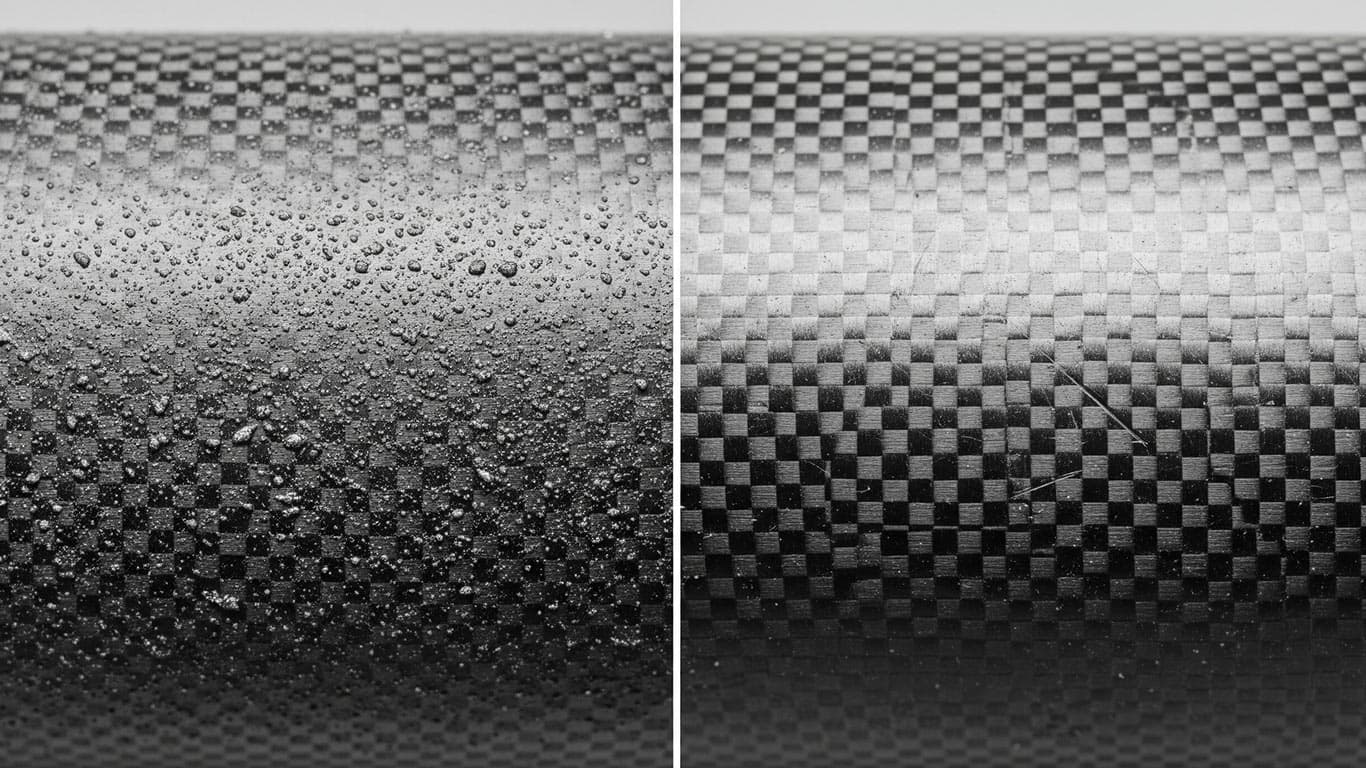

Carbon Fiber Reinforced Polymer

Cast Iron

Ceramic Matrix Composites CMCs

Concrete

Copper

Epoxy Resin Composites

Fiberglass

Granite

Iron

Limestone

Magnesium

Marble

Metal Matrix Composites MMCs

Nickel

Phenolic Resin Composites

Polyester Resin Composites

Porcelain

Sandstone

Slate

Stainless Steel

Steel

Terracotta

Titanium

Titanium Carbide

Tool Steel

Urethane Composites

Zinc

Titanium Alloy (Ti-6Al-4V)

Stainless Steel 316

Stainless Steel 304

Aluminum Bronze

Aluminum Nitride

Titanium Nitride

Paint Primer Layers Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more