Automotive Undercoating

Undercoating-contamination, this organic residue forms unique patterns on surfaces. It accumulates in layered films and irregular deposits, especially under protective coatings. Formation occurs gradually, as residues bond tightly with substrates, thus creating adhesion challenges. In laser cleaning applications, removal proves difficult; contamination resists ablation due to its dense structure and thermal stability. Material-specific behaviors emerge clearly—on metals, it spreads unevenly and absorbs energy poorly, so cleaning demands precise pulse control. After treatment, residue fragments scatter, yet stubborn patches persist in crevices. This contamination, it alters surface texture and demands multi-pass strategies for complete elimination. Process applies laser energy, thus breaks bonds and ejects particles. Challenges arise from re-deposition risks, following initial exposure. Efficiency improves with adjusted parameters, surface already shows reduced residue buildup.

Produced Compounds

Affected Materials

Aluminum

Brass

Brick

Bronze

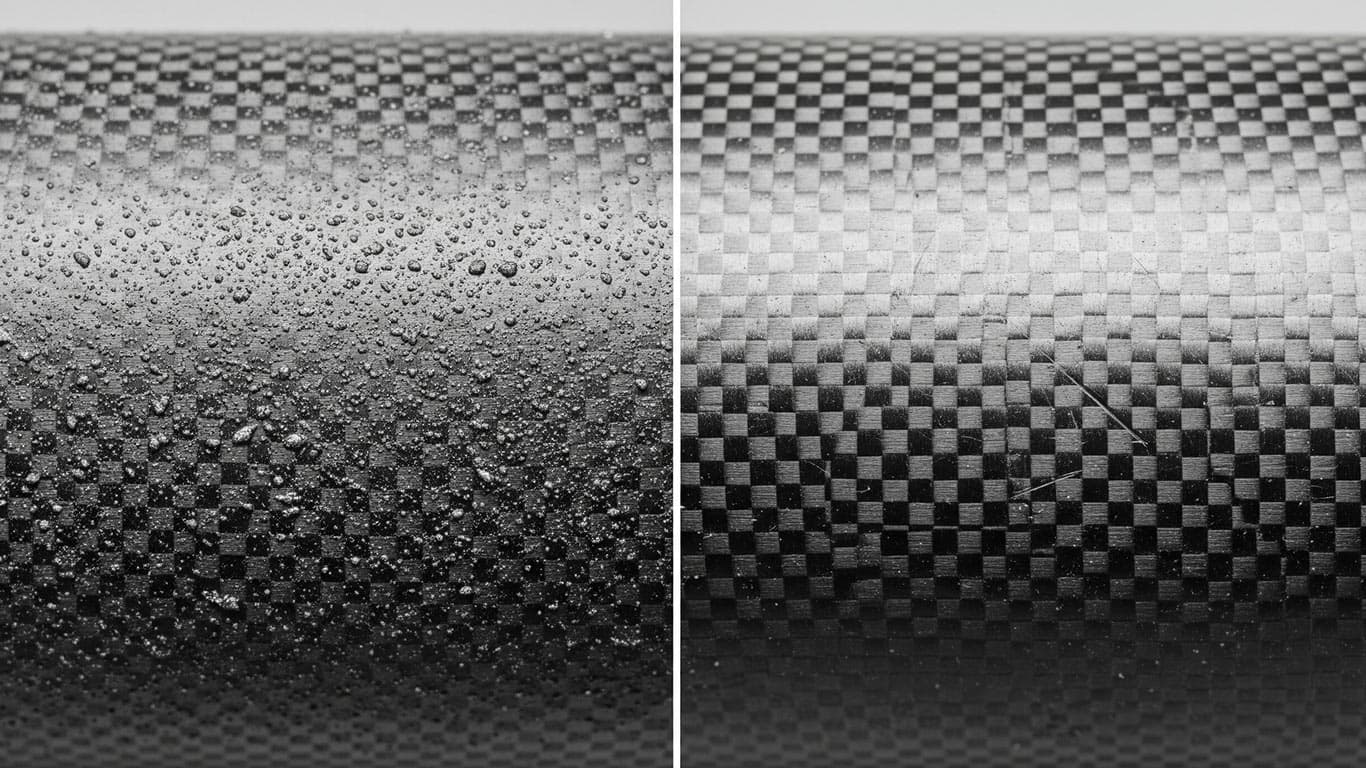

Carbon Fiber Reinforced Polymer

Cast Iron

Ceramic Matrix Composites CMCs

Concrete

Copper

Epoxy Resin Composites

Fiberglass

Granite

Iron

Limestone

Magnesium

Marble

Metal Matrix Composites MMCs

Nickel

Phenolic Resin Composites

Polyester Resin Composites

Porcelain

Sandstone

Slate

Stainless Steel

Steel

Terracotta

Titanium

Titanium Carbide

Tool Steel

Urethane Composites

Zinc

Titanium Alloy (Ti-6Al-4V)

Stainless Steel 316

Stainless Steel 304

Aluminum Bronze

Aluminum Nitride

Titanium Nitride

Automotive Undercoating Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more