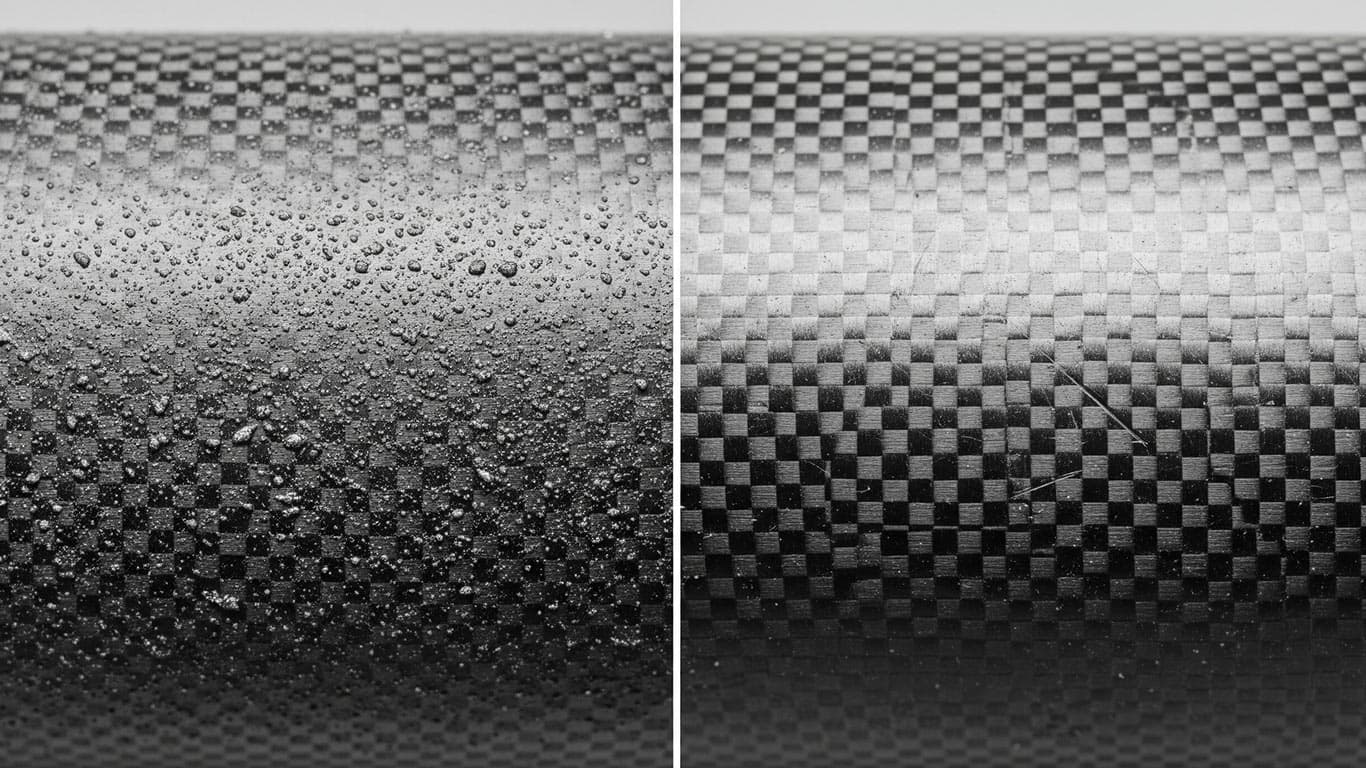

Wax Coating Buildup

Wax-buildup-contamination, it arises from organic residues in laser cleaning. This contamination forms unique patterns on surfaces. Layers accumulate slowly and adhere tightly to substrates like metals. Formation follows exposure to environmental waxes, thus creating uneven films. On polymers, it spreads broadly and penetrates pores. Removal challenges emerge here. Laser pulses struggle against its resilient structure. Heat from beams melts wax partially, so residue scatters but clings still. Material-specific behaviors differ greatly. Steel surfaces show stubborn buildup, it resists ablation easily. Glass, however, allows cleaner detachment after initial vaporization. Treatment applies, and efficiency improves with pulse adjustments. This contamination, it demands precise control to avoid substrate damage. Patterns reveal irregular deposits, thus complicating uniform cleaning. Organic nature makes it volatile yet sticky, so challenges persist in applications.

Yi-Chun Lin, Ph.D., Taiwan

Produced Compounds

Affected Materials

Aluminum

Brass

Brick

Bronze

Carbon Fiber Reinforced Polymer

Cast Iron

Ceramic Matrix Composites CMCs

Concrete

Copper

Epoxy Resin Composites

Fiberglass

Granite

Iron

Limestone

Magnesium

Marble

Metal Matrix Composites MMCs

Nickel

Phenolic Resin Composites

Polyester Resin Composites

Porcelain

Sandstone

Slate

Stainless Steel

Steel

Terracotta

Titanium

Titanium Carbide

Tool Steel

Urethane Composites

Zinc

Titanium Alloy (Ti-6Al-4V)

Stainless Steel 316

Stainless Steel 304

Aluminum Bronze

Aluminum Nitride

Titanium Nitride

Wax Coating Buildup Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more