Yi-Chun LinPh.D.Taiwan

Laser Materials ProcessingPublished

Jan 6, 2026

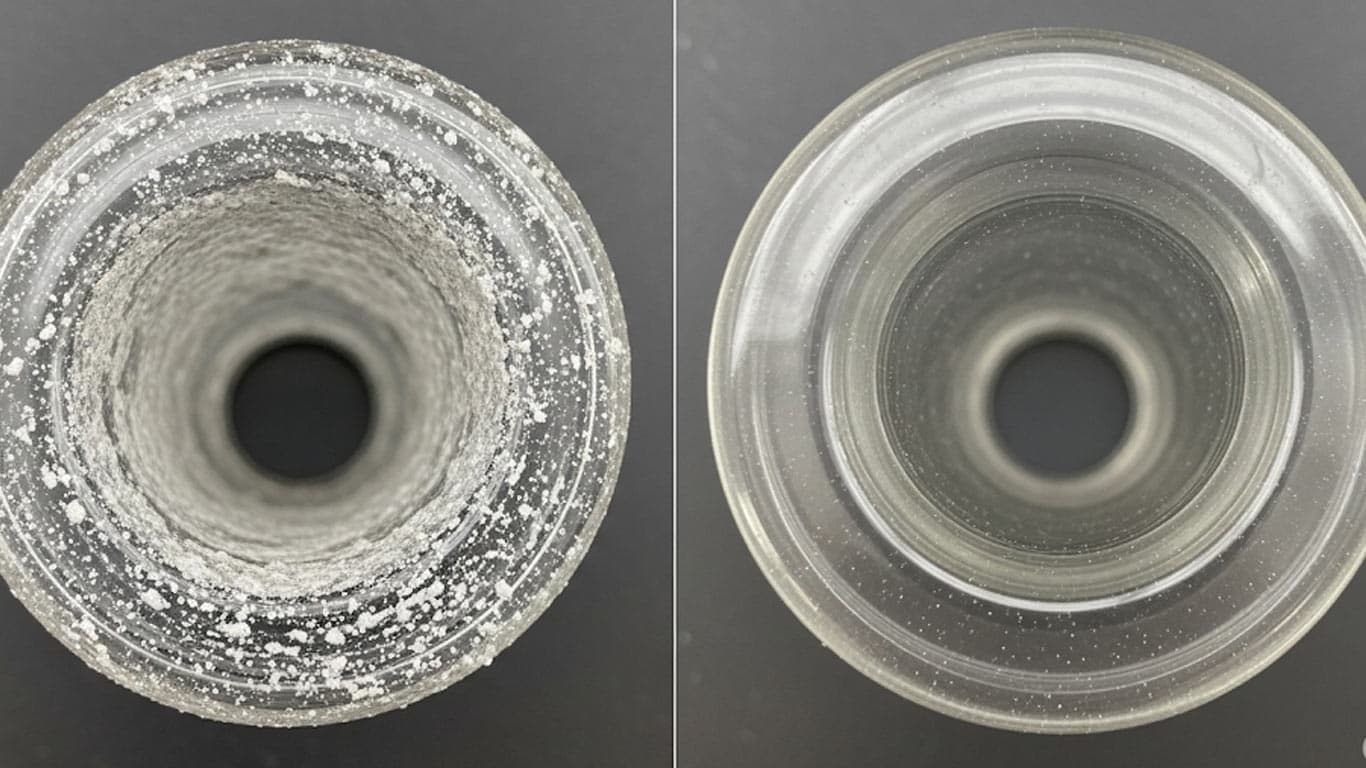

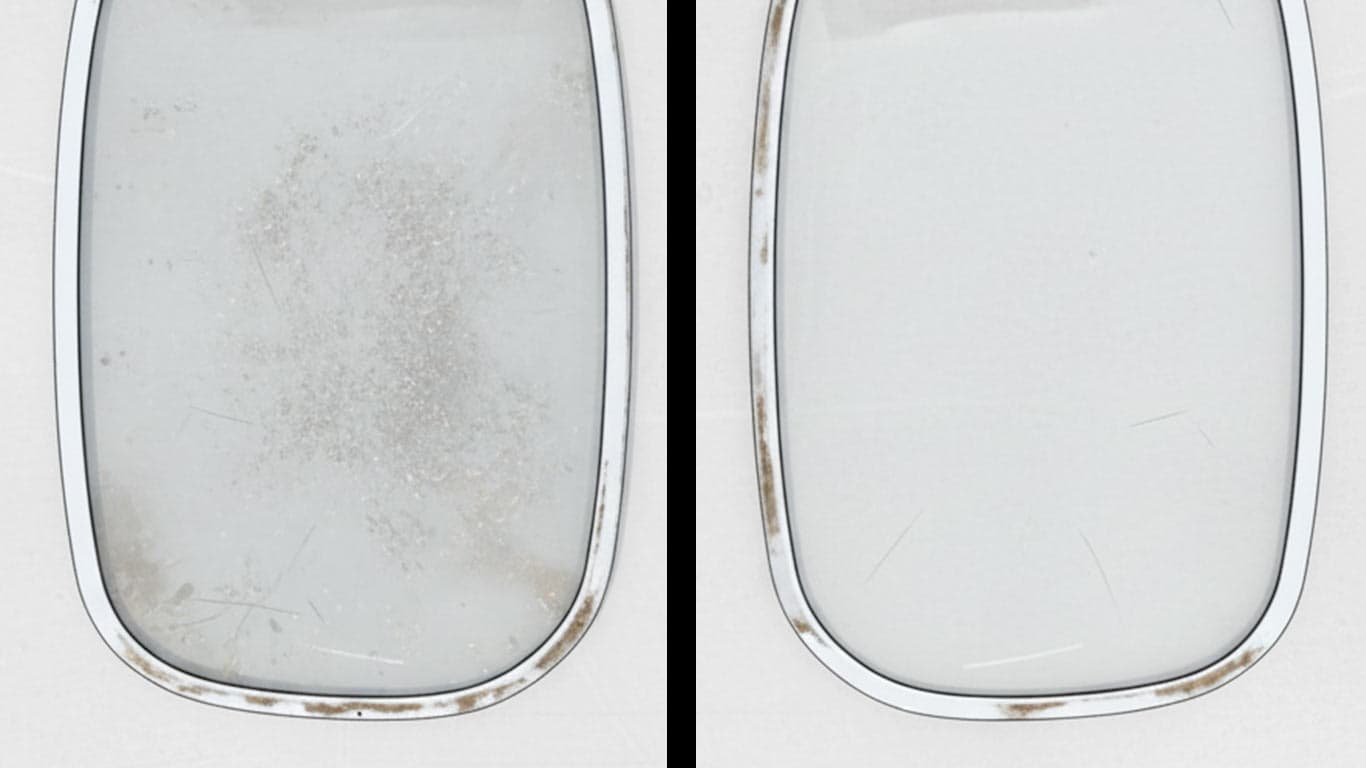

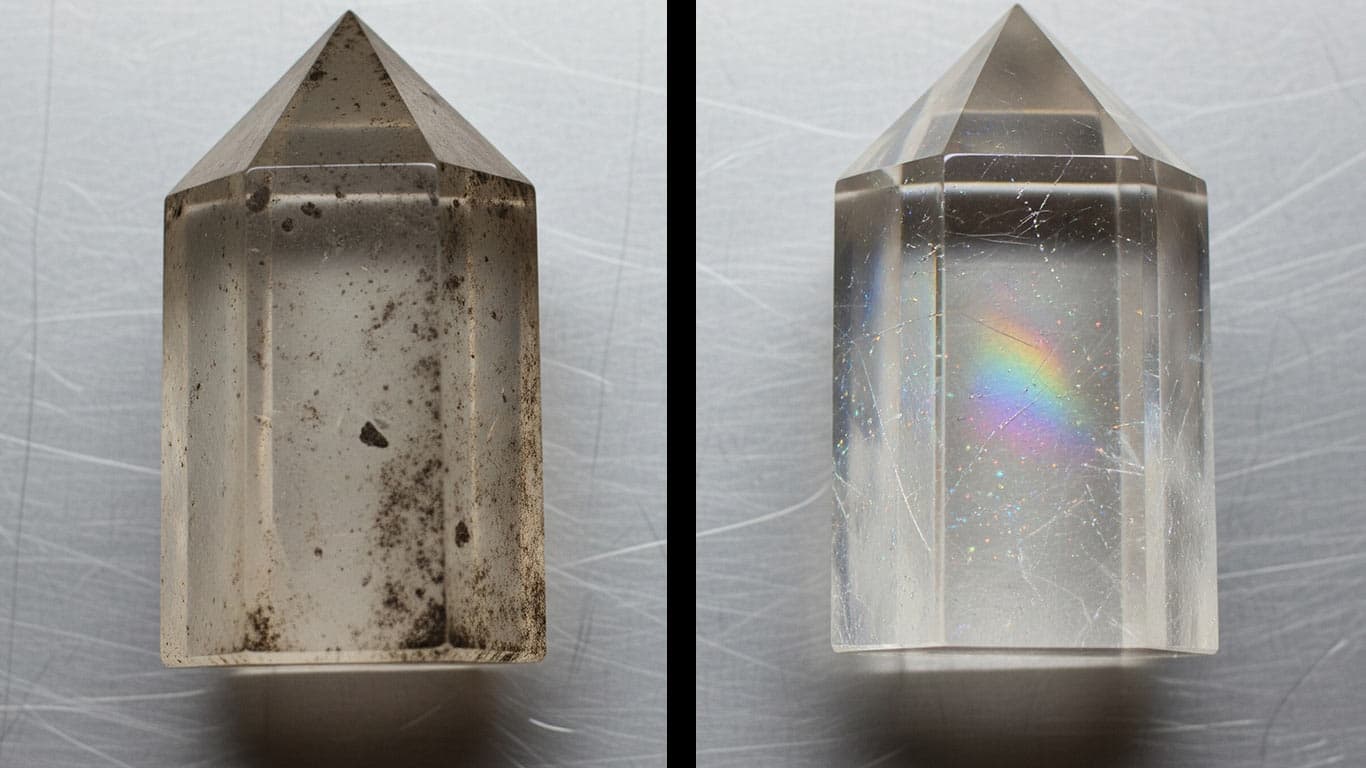

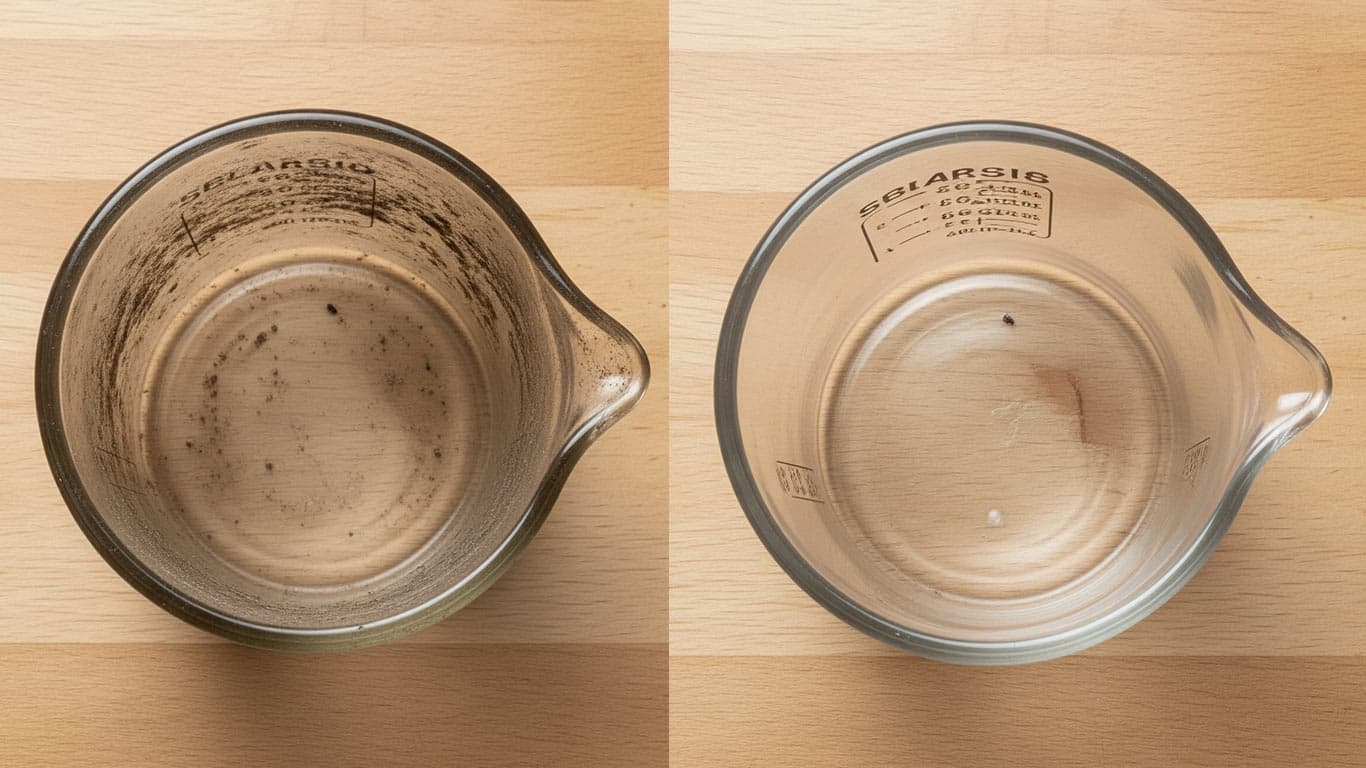

Engine Coolant Scale

Coolant-scale-contamination forms through thermal deposition. Scale builds on surfaces during coolant exposure, so layers adhere tightly. Before cleaning, contamination exhibits irregular patterns like crystalline buildup. In laser applications, removal challenges arise because heat intensifies bonding. On metals, it resists ablation and causes surface cracking. Treatment applies pulses, yet residue persists on alloys. After exposure, patterns vary by material, so selective wavelengths help. Process demands careful control to avoid damage. Results show uneven removal on substrates.

Produced Compounds

Hazardous compounds produced during laser cleaning

Affected Materials

Materials where this contaminant commonly appears

Aluminum

Borosilicate Glass

Brass

Bronze

Cast Iron

Concrete

Copper

Crown Glass

Fiberglass

Float Glass

Glass Fiber Reinforced Polymers GFRP

Gorilla Glass

Granite

Iron

Lead Crystal

Limestone

Magnesium

Marble

Nickel

Quartz Glass

Sandstone

Sapphire Glass

Slate

Soda-Lime Glass

Stainless Steel

Steel

Tempered Glass

Titanium

Titanium Carbide

Tool Steel

Zinc

Aluminosilicate Glass

Titanium Alloy (Ti-6Al-4V)

Stainless Steel 316

Stainless Steel 304

Aluminum Bronze

Aluminum Nitride

Titanium Nitride

Engine Coolant Scale Dataset

Download Engine Coolant Scale properties, specifications, and parameters in machine-readable formats

0

Variables

0

Safety Data

9

Characteristics

3

References

3

Formats

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more

Get Started

Schedule a service or reach out for more information